Inside Food Packaging Science: How Food Packaging Fits into the Circular Economy

Food packaging plays a critical role in modern life. It protects products from contamination, extends shelf life, and makes safe global distribution possible. But as soon as a package is emptied, a new question arises: what happens next?

Today, brand owners, regulators, and consumers are increasingly focused on the concept of a circular economy—a system where resources are reused, recycled, and kept in circulation for as long as possible. For food packaging, this shift means designing materials that not only safeguard food but also support sustainability goals once that packaging has served its primary purpose.

What Is the Circular Economy?

The traditional packaging model has long been linear: take resources, make a package, dispose of it. This “take–make–dispose” cycle has contributed to rising waste streams and environmental concerns.

By contrast, the circular economy is designed to:

Keep resources in use for as long as possible.

Extract maximum value from packaging while it is being used.

Recover and regenerate materials at the end of their useful life.

Applied to food packaging, the circular economy encourages companies to consider the full life cycle of a package: how it’s designed, what materials are used, how it’s collected, and how it can be recycled into new packaging.

A comparison of the traditional linear economy (‘take, make, use, dispose’) versus the circular economy (‘make, use, recycle or reuse, make again’), highlighting how resources can be kept in use for longer, reducing waste and supporting sustainability.

Why Recycling in Food Packaging Is Complex

Food packaging faces unique challenges that make recycling more complicated than other consumer goods:

Food Safety Requirements

Packaging must act as a reliable barrier to prevent contamination. Even trace levels of unwanted substances can impact quality or consumer trust.

Performance Demands

Packaging needs to withstand high temperatures, moisture, cold storage, and long transport times without breaking down. Achieving this often requires multi-material or multi-layer structures, which are harder to recycle.

Design for Recycling

Not all packaging is created with recyclability in mind. Laminated films, colored plastics, or incompatible additives can all reduce recyclability.

Additive Carryover

When recycled resins are used again in food-contact applications, any additives that migrate can carry over into the recycled material. This creates additional regulatory and technical considerations.

For example, flexible snack packaging often uses layered plastics to block oxygen and moisture. These layers protect the food but make recycling more difficult. Similarly, high migration additives may limit the use of recycled resins back into food-contact applications.

The Role of Additives in a Circular Economy

While materials like polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET) form the backbone of food packaging, additives are what make those plastics work. Antioxidants, stabilizers, and processing aids allow packaging to be manufactured efficiently, withstand harsh conditions, and remain safe throughout its use.

In a circular economy, additives take on an even bigger role:

Migration Profile

Additives with lower migration reduce the risk of substances carrying over into recycled resins. This makes it easier for those resins to be safely reused in new food packaging.

Stability During Reprocessing

Recycled resins undergo multiple heating and cooling cycles. Antioxidants and stabilizers protect against thermal and oxidative degradation, helping recycled plastics maintain their properties.

Regulatory Confidence

Food-contact approvals for additives give resin processors and brand owners confidence that recycled content will meet global safety standards.

Without the right additives, recycled plastics can lose performance quickly or fail to meet safety thresholds, limiting their use in food packaging.

Doverphos® LGP-12: Enabling Recycling and Circularity

Doverphos® LGP-12 was developed with these challenges in mind. As a polymeric phosphite antioxidant, it provides unique advantages that support both food safety compliance and circularity:

Low Migration Profile

Thanks to its larger polymeric structure, Doverphos® LGP-12 has a low migration profile and is cleared for use in food packaging, making it a trusted option for processors working with virgin and recycled resins alike.

Improved Processing Efficiency

As both an antioxidant and a processing aid, Doverphos® LGP-12 stabilizes melt flow, reduces gel formation, and minimizes die lip buildup. These benefits are especially valuable when processing recycled resins, which often have more variability than virgin feedstocks.

Support for Recycled Content Targets

Global brands are under pressure to incorporate higher levels of post-consumer recycled (PCR) content. Doverphos® LGP-12 helps stabilize those materials, enabling converters to meet performance expectations while advancing sustainability commitments.

Future-Ready Compliance

With regulations tightening in both the U.S. and EU, Doverphos® LGP-12 is designed to help brand owners and converters stay ahead of evolving standards.

Real-World Impact: Circular Packaging in Practice

Momentum for circular packaging is building quickly around the world:

European Union: The EU Packaging and Packaging Waste Regulation (PPWR) sets a target for all packaging to be reusable or recyclable by 2030, with specific goals for recycled content in plastic packaging.

United States: Several states, including California, have introduced extended producer responsibility (EPR) laws that require companies to take more responsibility for packaging waste.

Global Brands: Many food and beverage companies have pledged to include 25–50% recycled plastic in their packaging within the next decade.

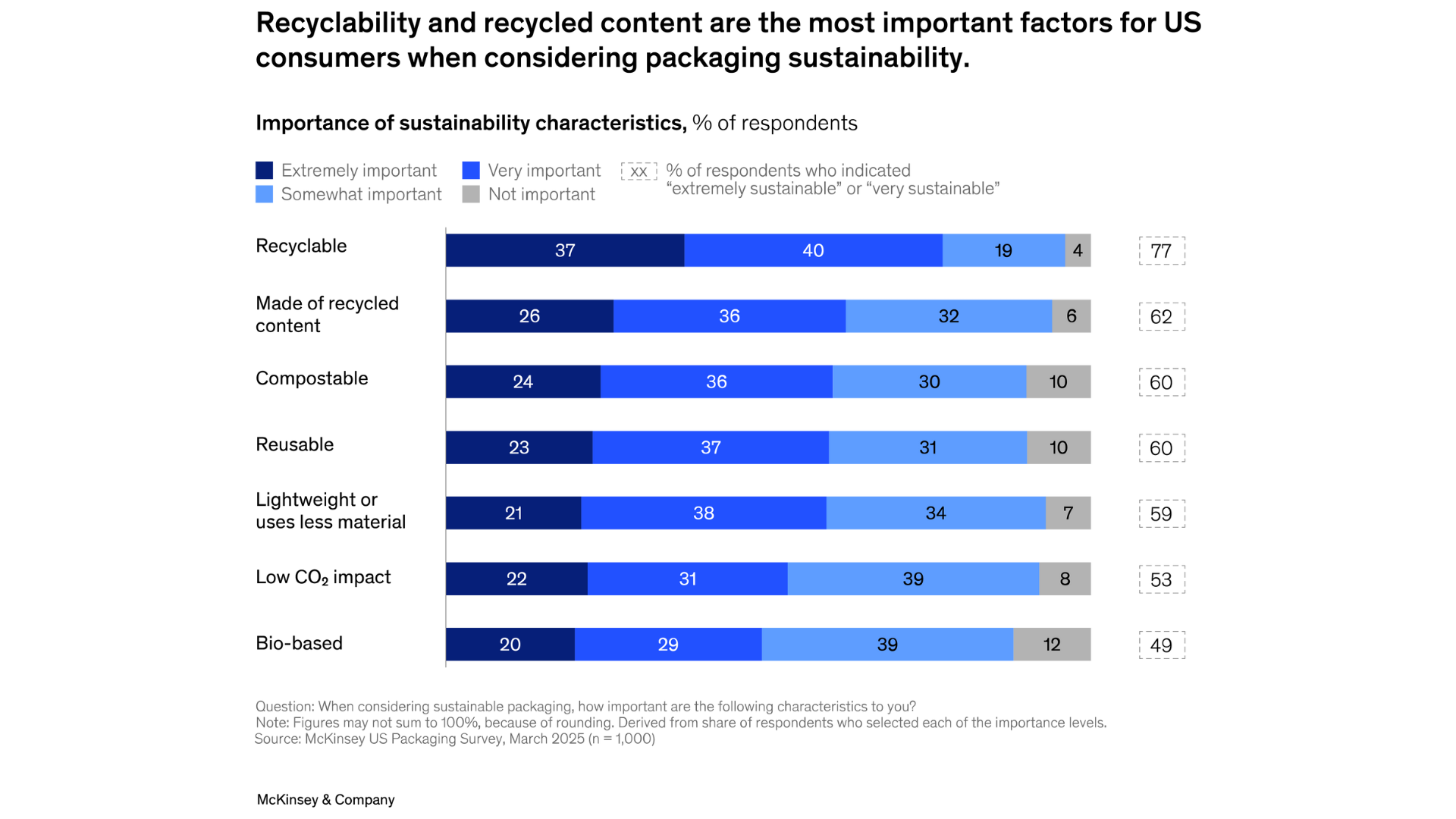

Consumer Demand: Shoppers increasingly look for packaging that signals recyclability, sustainability, or the use of recycled content.

To meet these expectations, packaging materials must perform at every stage—protecting food, meeting compliance, and recycling effectively. Innovative additives like Doverphos® LGP-12 help make these circular economy goals achievable in practice.

Consumer priorities in sustainable packaging: A majority of U.S. respondents rated characteristics such as recyclability, renewable materials, and overall environmental impact as very or extremely important. Source: McKinsey US Packaging Survey, March 2025.

Conclusion: Additives That Enable Circularity

The circular economy represents a new way of thinking about packaging. It’s not enough for a package to perform well in protecting food; it must also be designed for reuse and recycling.

Additives like Doverphos® LGP-12 play a critical role in this shift. By lowering migration, improving resin stability, and supporting recycled content goals, Doverphos® LGP-12 helps converters and brand owners create packaging that is safer, smarter, and more sustainable.

As the food industry continues to evolve, building a circular economy will require both innovation and collaboration. Inside Food Packaging Science will keep exploring how materials, additives, and design choices shape the future of packaging.